In the world of interior design and furniture, surface finishes play a fundamental role in the appearance and durability of products. Lamidecor, a leading company in the decorative paper market, presents an interesting new CPL finish. The Corteza pore will make any design stand out.

The term “CPL” stands for “Continuous Pressure Laminate”. It is a type of finish used on furniture surfaces, doors and other decorative elements. The CPL finish is obtained by combining thermosetting resins, decorative papers and melamine layers. This process is carried out under high pressure and temperature, creating a highly resistant and durable final product.

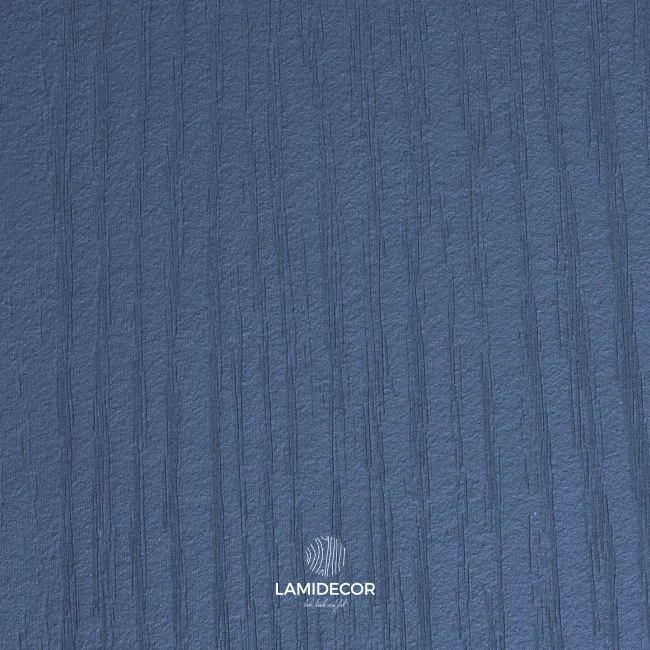

One of the most outstanding features of the Corteza finish of Lamidecor’s CPL Line is its matt appearance and its very marked wood structure. This provides a natural and authentic look, similar to real wood. The matt finish is also ideal for reducing reflections and fingerprints on surfaces, maintaining a clean and elegant aesthetic.

In addition, this Lamidecor pore is not only available for use with different types of wood, but also in a wide range of unicolours. This gives designers and manufacturers the freedom to explore various creative options for their projects. Whether it is a minimalist design or a bolder and more colourful one, Lamidecor’s CPL finish suits all needs.

The CPL is known for its high strength and durability. The laminated surface is resistant to scratches, bumps and daily wear and tear, making it an ideal choice for applications that require a robust and durable surface. In addition, Lamidecor’s CPL finish has excellent heat and chemical resistance, ensuring that designs retain their beauty over time.

Another significant advantage of Lamidecor’s CPL finish is its easy maintenance. Unlike some finishes that require special care, this type of finish is simple to clean and maintain in optimum condition. A soft, damp cloth is enough to keep the surface spotless.

Lamidecor‘s innovative CPL Cortex finish enhances any design with its visual and tactile appearance, giving designers creative freedom. From furniture to doors and panels, this finish adds character to the final products.

Lamidecor is a leader in the world of decorative paper, with a solid reputation for continuous innovation, quality and excellent customer service. The new Corteza finish offers a world of possibilities for designers and manufacturers in the field of furniture and interior design. Its matt finish and marked wood structure make it an interesting and natural choice, ideal for commercial and residential projects. With Lamidecor leading the decorative paper industry, designers can have full confidence in the quality and impact of their creations.

At Lamidecor, we are proud to present our Design Department, the creative heart of the company. Here at Lamidecor, we have a highly talented multidisciplinary team dedicated to creating realistic motifs for decorative paper design. Our aim is to bring you high quality designs that add beauty to any space.

The first step in the process of creating our designs is a state-of-the-art scanning of materials such as natural wood veneers. Veneers, marble and stone are carefully selected for their quality and beauty. We use state-of-the-art technology to capture very high resolution images that reflect every last pore of texture and depth of detail unique to each piece.

Once we have the scanned images, our design team processes them and creates beautiful, authentic designs. We use specialised software to manipulate the images, adjusting colours, contrasts and other elements to achieve stunning results.

Our design team draws inspiration from a wide range of styles, from the natural beauty of wood to other materials, fantasies and geometric patterns. Each design is created with dedication and attention to detail, to meet the needs and preferences of our customers.

Before launching our products on the market, we carry out extensive fit testing and retouching. It is important to ensure that the designs fit perfectly on different surfaces and maintain their natural appearance and texture.

Once the designs have passed the fit and touch-up tests, we proceed to the lacquering and finishing process. This stage is crucial to achieving the natural look and feel of our products. Numerous factors are taken into account, from the degree of gloss, to the haptic and visual texture. Our design team can create pores synchronised with the grain of the wood, as well as 3D embossed finishes, and even achieve an anti-bacterial surface.

We lacquer and finish to ensure that our products look authentic and durable. In this way, we ensure that the designs are protected and maintain their beauty over time.

At Lamidecor, we pride ourselves on offering the highest quality products that achieve a lifelike appearance and natural texture. Thanks to our careful creation process, our designs are realistic, detailed and create a warm and welcoming atmosphere in any space where they are used.

Aplicamos nuestros productos en diferentes superficies, como puertas, molduras, mobiliario y paneles, para brindarles un toque especial y transformarlos con estilo. Nuestro Departamento de Diseño de papel decorativo se esfuerza por crear diseños únicos y atractivos que satisfagan las necesidades y gustos de nuestros clientes. Ya sea que estés buscando revestir una puerta, decorar una moldura o darle un toque especial a tu mobiliario, nuestros productos son la solución perfecta.

We apply our products to different surfaces, such as doors, mouldings, furniture and panels, to give them a special touch and transform them with style. Our Wallpaper Design Department strives to create unique and attractive designs that meet the needs and tastes of our customers. Whether you are looking to cover a door, decorate a moulding or add a special touch to your furniture, our products are the perfect solution.

At Lamidecor we have a highly talented Design Department that is dedicated to creating realistic decorative paper motifs, from the scanning of the materials to the lacquering and finishing process. Each stage of our creation process is designed to deliver high quality products and add beauty and elegance to any space.

We are committed to providing aesthetic and functional solutions to our customers who wish to transform their environment with unique and quality designs. Feel free to contact us and discover the endless design possibilities we offer. We will be happy to work with you to transform your ideas into reality.

Laminates have emerged as a very popular and sustainable alternative to natural wood in the manufacture of furniture, doors and other similar products. These materials offer a number of advantages that make them an increasingly common choice in the industry. In this article, we will explore what laminates are, why they are a sustainable alternative and how they are used in the manufacture of furniture and doors.

Laminates are composite materials made by bonding several layers of paper impregnated with resins and subjected to high pressure and temperature. This combination of layers gives laminates greater strength and durability compared to natural wood.

Lamidecor’s CPL (Continuous Pressure Laminate) laminates offer a number of benefits that are attractive to both manufacturers and consumers. Some of these benefits include:

Laminates are used in a wide range of applications in the manufacture of furniture and doors. Some of the areas where they are used most frequently are:

In summary, Lamidecor CPL laminates are a more sustainable and versatile alternative to natural wood in the manufacture of home furnishings. Their strength, durability and wide design variety make them an attractive choice for both manufacturers and environmentally conscious consumers.

Transition joints for flooring are essential elements in construction projects for several reasons. Firstly, they ensure a smooth and safe transition, which is especially relevant in high-traffic areas or where accessibility is required. These joints also protect floors against wear and damage, prolonging their service life and reducing long-term maintenance costs. In addition, they contribute to the overall aesthetics and design of the space, as they are available in a wide range of styles, colours and finishes.

Transition profiles are particularly useful for covering expansion joints, especially in areas such as doors and staircases. In addition to serving a practical function, a well-chosen transition profile beautifies the space and covers imperfections between the floor and adjacent elements.

When it comes to the aesthetics of flooring, it is not only the material used but also the finishing accessories that must be considered. Transition profiles are key elements for joining different floor coverings, such as tiles and decking. But how do you choose the right profiles and are they really necessary for all floors?

Transition joints come in a variety of shapes and styles, designed to suit different needs and preferences. Here are some common types of transition joints:

When choosing transition profiles, it is important to consider the colour and design that matches the floor in question. Opting for profiles that reflect the structure and design of the wood is a wise choice. In this respect, Lamidecor stands out as an expert in the manufacture of decorative paper for transition joints.

Transition joints offer a number of significant benefits for parquet floors:

Lamidecor offers a wide variety of decorative paper designs that imitate wood in a surprisingly realistic way. These decorative papers adapt to different types of flooring, such as laminate, vinyl and parquet, providing an aesthetic and functional finish. The quality, durability and moisture resistance of Lamidecor products make them an ideal choice for beautifying transition joints.

In addition to their attractive visual appearance, Lamidecor decorative papers offer a practical solution for protecting expansion joints against the penetration of dirt, sand or dust.

Lamidecor’s selection of transition profiles is extensive and offers a variety of styles, colours and surfaces. From designs that imitate wood for a warm, natural look to metallic colours, the profiles coordinate perfectly with the décor of laminate and other types of flooring.

Lamidecor stands out as an expert in the manufacture of decorative paper, offering a wide range of imitation wood or fantasy designs. Its quality, durability and moisture resistance products provide practical and aesthetic solutions to embellish transition joints in any environment. With Lamidecor, it is possible to create a unique and welcoming environment, where every detail contributes to a harmonious and attractive design.

Transform your spaces with elegance and style with Lamidecor.

From the receipt of raw materials to the shipment of the finished product, each stage is carried out with meticulousness and care to ensure quality and customer satisfaction. With advanced technology and customised designs, Lamidecor stands out as a leading manufacturer of decorative paper. We tell you all the steps below:

Once we have the raw materials, we move on to the creation of the decorative paper design. We use advanced technology and the experience of our professionals to develop customised and attractive designs that meet the high expectations of our customers.

At Lamidecor, we use two printing models, “hollow” and “digital”, to create decorative paper.

Gravure Printing

Lamidecor is proud to offer high quality gravure printing services. Our attention to detail and commitment to excellence has made us a market leader. We use different types of inks, such as water-based organic inks, conventional inks in various colours and special inks such as metallic inks and 3D varnish. Meticulous ink preparation is crucial for impressive results, which is why we employ a rigorous measuring process using specialised devices such as a printing proofer and spectrophotometer. This preparation ensures high-quality, long-lasting prints that are true to design.

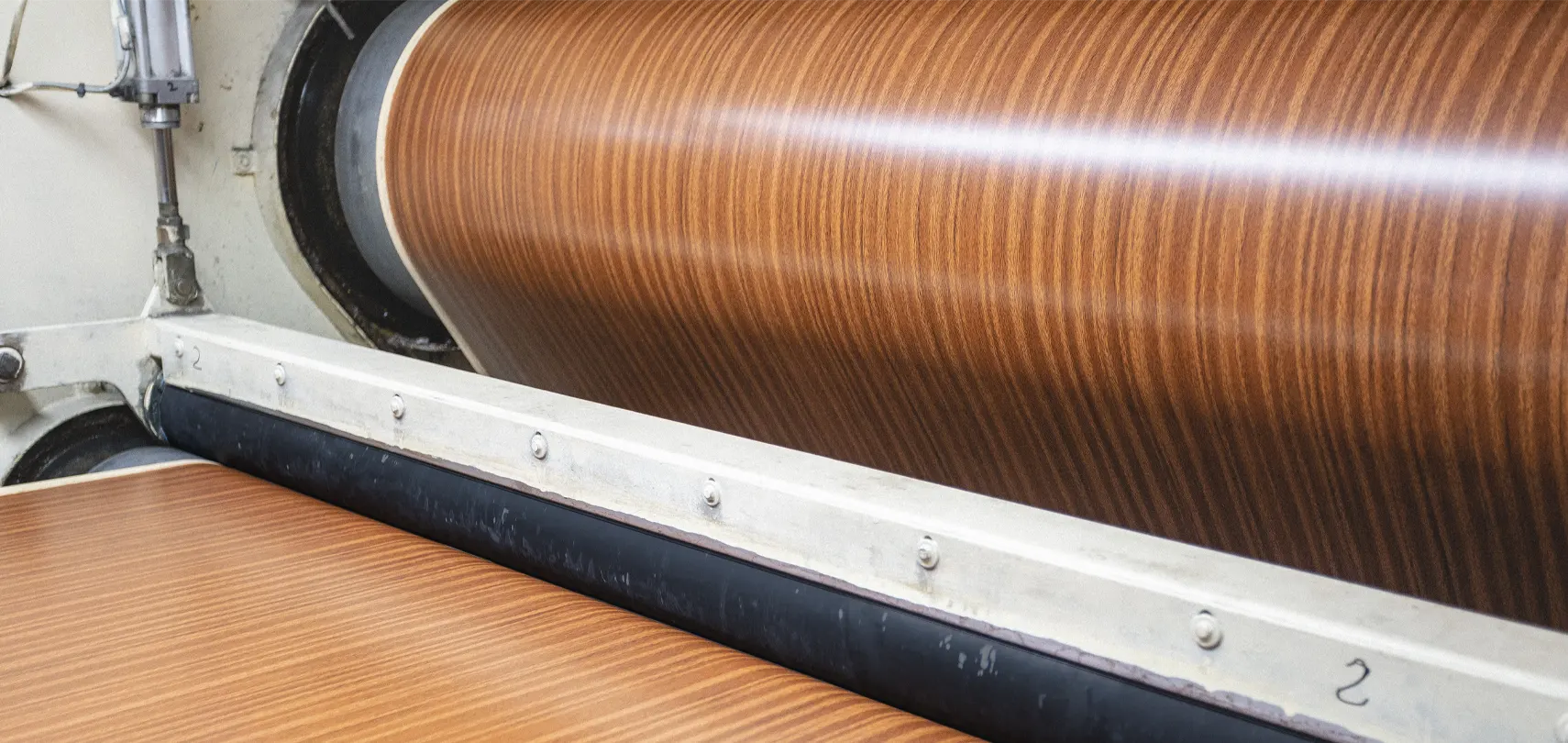

Today we can say that the rotogravure printing line is the most effective in achieving a realistic reproduction of any material.

The secret of quality printing is a team of expert technicians who know and work the entire process with professionalism and dedication at every step. From the choice of inks to the adjustment of cylinders. This process is fast and efficient, and is also suitable for the production of large print runs. The result is a wide range of woodgrain, fantasy and unicolour designs on decorative paper.

Digital Printing

With digital printing we can capture any idea with great precision and detail.

It is done by injecting LED UV inks on paper or vinyl. The process begins by sending a digital file to the printer, which processes it and translates it into commands for the print head. The printheads spray the UV LED inks in specific patterns to create the desired image. Curing occurs immediately thanks to the ultraviolet light emitted by the lamps. Our digital product line offers high quality, high resolution custom designs with fast turnaround times. We have a team of skilled technicians who complete the process with professionalism and dedication to ensure a quality print.

Impregnation and coating process of printed paper: The transformation from paper to Design

Once printed, the paper undergoes an impregnation process. At this stage, a protective coating is applied to the paper to improve its resistance to abrasion and water. This ensures that the decorative paper maintains its appearance and quality over time.

The process of impregnating and coating printed paper is essential to transform it into high-quality decorative paper. Impregnation involves dipping the paper in a solution that gives it additional properties such as water resistance, gloss and durability. Specific chemicals such as melamine, urea and phenolic resins are used. A coating of lacquer is then applied to provide additional strength and gloss. The types of lacquers used vary according to the paper application, such as urethane, acrylic and nitrocellulose lacquer. Impregnated and lacquered paper is used in paper for furniture, doors, profiles, skirting boards, panels, mouldings, etc. providing greater durability and a decorative appearance.

After impregnation, the paper undergoes a lamination process for CPL products. Here, one or several additional layers are added, which can be made of different materials, such as resins or vinyl, depending on the customer’s needs. This lamination provides increased durability and strength to the decorative paper. As well as an aesthetic full of textures that make the paper disguise with reality.

Once the lamination is complete, the paper undergoes a final coating process. This lacquer coating provides a glossy finish and protects the paper from stains and scratches. It also brings out the colours and details of the design, giving a high quality final appearance.

Finally, once the decorative paper has gone through all these stages of production, it undergoes a thorough quality check and is then packed and shipped. We ensure that the product reaches our customers in perfect condition, ready to be used to cover flat and curved surfaces such as panels, doors, furniture, mouldings and skirting boards.

At Lamidecor, we pride ourselves on offering our customers a complete and controlled manufacturing process, together with high quality products and customised designs. Our extensive experience in the sector allows us to meet the most demanding expectations and provide full comfort to our customers.

Trust in Lamidecor’s experience to obtain high quality products and unique designs that will transform your spaces.

Profile coating is an essential process in the furniture and construction industry. In order to improve the appearance and durability of profiles used in doors, windows, furniture and other architectural elements, different materials such as finish foil, CPL (Continuous Pressure Laminate) and vinyl are applied. These coatings provide a protective and aesthetic layer, allowing profiles to be customised according to customers’ preferences and needs.

Finish foil is a versatile coating that consists of a thin sheet of paper impregnated with resins and coated with a protective layer for strength and durability. It provides protection against wear, moisture and UV rays, but its great advantage is its great flexibility, allowing a bending radius of up to 1 mm. On the other hand, CPL is a continuous pressure laminate, composed of layers of paper impregnated with phenolic and melamine resins. It is also highly resistant to impact, abrasion and chemicals. Vinyl, on the other hand, is a customisable coating as it is digitally printed. It is water resistant and easy to clean, making it a popular choice for wet environments such as kitchens and bathrooms.

Profile cladding with foil finish, CPL and vinyl offers several significant advantages. Some of these are:

Profile cladding is used in a variety of applications, such as:

To preserve the appearance and durability of coated profiles over the long term, proper maintenance is important. Some tips include regular cleaning of coated profiles with mild, non-abrasive products, avoiding the use of sharp or abrasive objects that can damage the surface.

Profile coating is a constantly evolving field, and some notable trends include:

These materials make it possible to improve the appearance of profiles, extend their service life and adapt them to different styles and needs. Whether on doors, windows or furniture, profile cladding is a versatile and durable solution. As technology advances and new trends emerge, profile cladding will continue to play a crucial role in the furniture and construction industry.

Single-ply edgebanding is an essential element in the furniture and decoration industry. At Lamidecor, as well as being leaders in high quality decorative paper for furniture covering. We are also specialists in the manufacture of single layer edgebanding with a track record of almost 40 years.

In this article, we will give you a complete overview of single-ply edgebanding, its characteristics and applications.

In the field of furniture manufacturing and joinery, edging is an essential element to provide an elegant appearance and protect the edges of boards. Single-ply edgebanding is a popular choice due to its versatility and aesthetic quality.

Edgebanding is done by applying it to the edge of the panel. This strip is adhered to the panel using different methods, such as hot melt adhesives, liquid adhesives or pressure systems. It is a common process in furniture manufacturing. It is used to cover the exposed edges of plywood, MDF or other materials used in furniture construction. The purpose of edgebanding is to provide an aesthetic appearance and to protect the edges from damage.

The single layer edgebanding is composed of a single high quality decorative paper of 170 to 200 grams/m2 and has a thickness of approximately 0.3 mm. This type of edgebanding offers a wide variety of textured and porous finishes similar to the main board. They are easy to install and adhere perfectly to the board using hot-melt techniques.

Single-ply edging is characterised by the following features:

Single-layer edgebanding offers several advantages for the furniture industry. In addition to protecting the edges of furniture against impact, moisture and wear, it also provides an aesthetic appearance, hiding the inner layers of the panel and giving a uniform finish. In addition, the edge coating facilitates the cleaning and maintenance process of the furniture.

Among its advantages we highlight:

Single layer edgebanding is used in a wide range of applications, such as kitchen furniture, bathroom furniture, office furniture, general home furnishings, as well as in the commercial and display environment. Its versatility and strength make it an ideal choice for customised and durable finishes on different types of furniture.

When choosing the right single-ply edgebanding for your furniture, you should consider factors such as design style, colour scheme and the level of protection required. There are different design and finish options to suit your specific needs.

Lamidecor’s digital printing on single-layer edgebanding offers numerous advantages. It allows you to create personalised and detailed finishes that adapt to the tastes and needs of the client, guaranteeing exceptional and long-lasting visual quality. This technology provides greater design freedom by creating complex patterns, detailed images and customised colour combinations, as well as accurate reproduction of textures and finishes, resulting in a realistic and aesthetically appealing look. In addition, digital printing in the field of monolayer edging allows for more efficient and flexible production, streamlining the production process and reducing lead times. Material waste is also minimised by printing only the required amount of customised edging.

In summary, single layer edgebanding is an ideal solution for furniture cladding, offering a perfect finish to the edges of the panels. Its characteristics, advantages and applications make it a versatile and aesthetic material. At Lamidecor, as a leading company in the industry, we guarantee the quality and customisation of our monolayer edging to meet the specific needs of our customers in the furniture and decoration sector.

Finish foil, also known as decorative foil, is an outstanding material in the field of surface coating. It is a thin paper foil impregnated with resins and coated with a protective layer for strength and durability. Finish foil offers a wide variety of designs and finishes, making it a popular choice for adding a decorative look to various types of furniture.

Finish foil is widely used in the furniture industry as it offers an effective and versatile solution for surface coating. Some of the most common applications include the coating of furniture, doors, cabinet fronts, mouldings and profiles as well as the creation of decorative panels.

One of the main advantages of the is its durability and strength. Despite its delicate appearance, this material is able to withstand knocks, scratches and other types of wear and tear, thanks to the protective coating finish. In addition, finish foil offers a wide range of designs and finishes to suit different styles and preferences.

Another important advantage of finish foil is its ease of installation and maintenance. It can be applied to a variety of substrates, such as chipboard or MDF, using pressing or gluing techniques. In addition, its smooth, non-porous surface makes it easy to clean and maintain on a daily basis, without the need for special products.

Finish foil stands out in the furniture industry due to its versatility and design flexibility. There are multiple design options that mimic wood, unicolours, patterns and other decorative elements. This allows furniture manufacturers to offer a wide range of options to customers, adapting to different styles and preferences.

Compared to other materials used for surface coating, finish foil offers several competitive advantages. Firstly, it is a more affordable option in terms of cost. It allows high quality finishes to be obtained at a more affordable price, which is an important consideration in projects with budget constraints.

This material used in the furniture and furnishing industry offers a number of advantages, not least of which is its flexibility. One of the main characteristics of finish foil is its ability to bend up to a bending radius of 1 mm.

This property of flexibility gives it multiple benefits in the field of furniture and cladding design and installation. The following are some of the most relevant advantages:

In conclusion, finish foil is a star product in Lamidecor’s surface coating. Its variety in fantasy and unicolour woods, its durability, its easy installation and maintenance, as well as its cost-effectiveness, make it a popular choice in the furniture industry.

Lamidecor is positioned as a leading company in this field, offering high quality products and customised solutions to meet the needs of our customers.

In the world of interior design, Lamidecor’s decorative laminates have become a popular choice for creating aesthetically appealing and functional environments. These laminates offer a wide range of designs, finishes and applications, making them a versatile option for transforming any space.

Durability and strength

Lamidecor’s decorative laminates are recognized for their durability and strength. These materials are designed to withstand daily use and resist wear and tear over time. The combination of paper layers impregnated with synthetic resins and the high temperature and pressure process to which they are subjected during their manufacture gives them a solid and resistant structure.

They are capable of resisting knocks, scratches and dents, making them an ideal choice for areas of high traffic and intense use. In addition, they are resistant to stains and fading, ensuring that they retain their original appearance for many years.

Their durability is also enhanced by their ability to resist moisture and weathering. Lamidecor’s decorative laminates are designed to be resistant to environmental humidity, preventing them from warping or deteriorating over time.

In addition, these laminates are easy to clean and maintain. Their smooth, non-porous surface prevents the accumulation of dirt and facilitates cleaning with a damp cloth and mild detergents. They do not require specialized maintenance, making them a convenient, low-maintenance option for any space.

Lamidecor’s decorative laminates offer a wide variety of interior design applications. Some of the most common applications include:

Decorative laminates are ideal for the manufacture of furniture, such as tables, chairs, cabinets and shelving. Their variety of designs and finishes makes it possible to create furniture pieces to suit different styles and aesthetic preferences. In addition, their scratch resistance and easy maintenance make them a practical and durable option for everyday furniture.

When selecting decorative laminates from Lamidecor, it is important to consider the following aspects::

Before choosing decorative laminates, it is important to consider the mood and theme of the space where they will be used. For example, if you are looking for a modern and minimalist style, you can choose laminates with neutral colors and simple designs. For a warmer and cozier atmosphere, laminates with wood patterns can be an excellent choice. Lamidecor offers a wide variety of designs and finishes to suit different aesthetic preferences.

Depending on the use and location, high quality laminates should be selected that are suitable for resisting wear, impact, stains and moisture, ensuring long life and a flawless appearance over time.

It is also important to select decorative laminates that are compatible with the environment in which they will be installed. This involves taking into account factors such as lighting, existing furnishings and wall colors. Laminates should complement and enhance the environment, creating visual harmony in the space.

In conclusion, Lamidecor’s decorative laminates offer a wide variety of designs: fantasy woods and unicolors to suit different styles and aesthetic preferences. Their strength, durability and ease of maintenance make them a popular choice for a variety of interior design applications.

At Lamidecor, we pride ourselves on providing high quality rotogravure printing services. Our attention to detail and commitment to excellence has made us a market leader. In this article, we will explore how we work with and prepare inks to ensure impressive results for every project. We will cover the types of inks we use, such as water-based organic inks, conventional inks in colours such as yellow, orange, red, black, blue and white, and special inks, such as metallic and 3D varnish, which offer unique visual effects and sync with wood or textile designs. We will also describe our ink measurement process, highlighting the importance of achieving an accurate formula for precise colours for each print.

At Lamidecor, we understand that proper ink preparation is crucial to achieving high quality results in gravure printing. Our team of experts ensures that each ink is ready for use, guaranteeing its fluidity, adhesion and durability on the substrate.

At Lamidecor, we use different types of inks to adapt to the specific needs of each project. Our organic inks are renowned for their quality and lightfastness. We also offer water-based inks, which are a more ecological and sustainable option, as they are formulated with water-based inks instead of chemical solvents.

In addition, we have a wide range of conventional inks in vibrant colours such as yellow, orange, red, black, blue and white. These inks allow us to print full-colour images with great accuracy and fidelity. We also offer special inks, such as metallic inks and 3D varnish, which add a natural realism to designs. These special inks can be synchronised with wood or textile designs, allowing us to offer unique and stunning prints.

At Lamidecor, we ensure that every print is perfect and meets the highest quality standards. To achieve this, we have a rigorous ink measurement process. We use Printing Proofer, a specialised device that allows us to adjust the pressure and speed of ink transfer to achieve accurate and consistent results. This ensures accurate colour reproduction on every print.

We also use the spectrophotometer, a state-of-the-art tool, to analyse the colour of the ink. This provides us with a precise formula to obtain the exact colour charge. This meticulous measurement ensures that each print is reproducible without variations in future reproductions. At Lamidecor, we strive to deliver results

Proper ink preparation at Lamidecor offers numerous advantages for both us and our customers. First of all, it enables us to offer high-quality, long-lasting prints. The right choice of inks, their careful preparation and precise metering ensure impressive results in terms of colour, sharpness and detail.

In addition, ink preparation allows us to optimise ink usage, avoiding unnecessary waste and reducing costs. It also ensures consistent colour reproduction in every print, which is essential for projects that require exceptional fidelity and accuracy. Our customers rely on us to faithfully reproduce their designs, and our meticulous ink preparation enables us to meet those expectations.

At Lamidecor, ink preparation is a fundamental aspect of our rotogravure printing work. Through the use of organic inks, water-based inks, conventional inks in a wide range of colours and special inks, we offer our customers creative options and stunning results. Our ink measurement process, using tools such as the Printing Proofer and spectrophotometer, allows us to ensure accurate and consistent colour reproduction in every print.

Preparing inks properly is a crucial step to successful gravure printing!