As a property owner or manager, you want to ensure that your doors are not only functional, but also aesthetically pleasing. One way to achieve this is through door resurfacing. Door resurfacing is the process of applying a material to the surface of a door to improve its appearance and durability. There are many types of cladding materials available on the market, but one that stands out is melamine laminate. In this article I will explain why melamine laminate is the best choice for door cladding.

Introduction to door flooring

Door resurfacing is a process of applying a material to the surface of a door to improve its appearance and durability. Coating can be applied to both interior and exterior doors. The most commonly used materials for door cladding are laminates, veneers and paint. Each material has its advantages and disadvantages. However, melamine laminate is one of the best materials for door cladding.

Melamine laminate is a type of laminate that is manufactured by combining melamine resin and paper. The paper is impregnated with melamine resin and then bonded together under high pressure and temperature. This process creates a durable, scratch-resistant material that is ideal for use in door casings.

Melamine laminate is available in a wide range of colours and designs, making it easy to find one that matches your décor. The material is also easy to clean and maintain, making it a popular choice for high traffic areas such as offices and commercial buildings.

Using melamine laminate for door cladding has many advantages. One of the main benefits is its durability. Melamine laminate is highly resistant to scratches, stains and fading, making it ideal for use in high traffic areas.

Another advantage of using melamine laminate for door cladding is its affordability. Compared to other materials such as veneers and solid wood, melamine laminate is much cheaper. This makes it a great option for those on a tight budget.

Melamine laminate is also easy to install. The material can be cut to size and applied to the door surface with adhesive. This makes it a popular choice for do-it-yourselfers.

Melamine laminate can also be used for frame construction. The material is ideal for this purpose due to its durability and resistance to moisture. Melamine laminate frames are also easy to clean and maintain, making them ideal for use in areas such as bathrooms and kitchens.

When it comes to melamine laminate door cladding, there are several corner options available. These include square corners, rounded corners and bevelled corners. The choice of corner option will depend on your personal preferences and the style of your décor.

Melamine laminate is not the only type of laminate available on the market. Other types of laminates are finishing laminates and CPL (continuous pressure laminates). Finishing laminates are manufactured by impregnating paper with a thermosetting resin and then bonding it to a substrate under heat and pressure. Continuous pressure laminates are manufactured by impregnating paper with a thermosetting resin and then bonding it to a substrate under continuous pressure.

Compared to other types of laminates, melamine laminate is more durable and scratch resistant. It is also more affordable and easier to install. In addition, melamine laminate is available in a wider range of colours and designs.

Melamine laminate door facings are easy to clean and maintain. To clean the door surface, simply use a soft cloth and mild detergent. Avoid using abrasive cleaners or scouring pads as they may scratch the laminate surface.

Cost-effectiveness of melamine laminate door facings

As mentioned above, melamine laminate is one of the most cost-effective materials for door panelling. Compared to other materials such as veneers and solid wood, melamine laminate is much more affordable. This makes it a great option for those on a tight budget.

Melamine laminate is available in a wide range of colours and designs. Some of the most popular designs include wood grain, marble and solid colours. The choice of design will depend on your personal preferences and the style of your décor.

In conclusion, melamine laminate is the best choice for door cladding. It is durable, scratch-resistant, easy to install and affordable. Plus, it’s available in a wide range of colours and patterns, so it’s easy to find one that matches your décor. If you want to enhance the look and durability of your doors, consider using melamine laminate for door cladding.

Laminate is a versatile and economical material used in a wide variety of applications. One of the most common uses of laminate is in the manufacture of furniture. Laminate furniture has a durable, stain and scratch resistant finish, making it ideal for homes with children and pets. In this article, we’ll tell you everything you need to know about furniture laminate, from how it’s made to how it’s cleaned and maintained.

Furniture laminate is a material composed of several layers of decorative paper impregnated with melamine resins, pressed at high temperature and pressure onto a core of MDF, chipboard or plywood. The decorative paper can mimic any surface, from wood and stone to metal and leather, and the melamine resin gives the laminate a wear-resistant and easy-to-clean surface.

Furniture laminate offers many advantages over other materials. Here are some of the most important ones:

1. Durability

Laminate is highly resistant to stains and scratches, making it ideal for homes with children and pets. It is also water resistant, making it suitable for wet areas such as bathrooms and kitchens.

2. Variety of designs

Laminate comes in a wide variety of designs and colours, which means it can mimic any surface you want, from wood and stone to metal and leather. You can also find laminate with customised patterns and designs.

3. Easy to clean and maintain

Laminate is very easy to clean and maintain. You only need to wipe the surface with a damp cloth to remove dirt and dust. Moreover, it does not need to be waxed or polished.

4. Economical

Laminate is cheaper than other materials such as solid wood and glass. This means you can get the look you want at an affordable price.

The process of manufacturing furniture laminate is quite simple. Here are the main steps:

1. Surface preparation. The surface of the MDF, chipboard or plywood is cleaned and sanded to ensure optimum adhesion.

2. Preparation of the decorative paper. The decorative paper is cut into strips the width of the sheet and impregnated with melamine resins.

3. Pressing of the laminate. A layer of impregnated decorative paper is placed on the MDF, chipboard or plywood core and pressed at high temperature and pressure to melt the resin layers and create a uniform and resistant surface.

4. Edge finishing. To give a uniform and aesthetically pleasing finish, the edge of the laminate is taped or profiled with a specialised machine.

5. Quality inspection. A quality inspection is carried out to ensure that the laminate meets standards for strength, durability and finish.

Laminate furniture is very easy to clean and maintain. Here are some tips for keeping laminate in good condition:

1. Clean regularly

Wipe laminate regularly with a soft, damp cloth to remove dust and dirt.

2. Do not use abrasive products

Do not use abrasive products such as steel wool or acidic cleaners as they can damage the surface of the laminate.

3. Use surface protectors

Use surface protectors such as coasters and tablecloths to avoid stains and scratches on the laminate surface.

4. Avoid exposure to direct sunlight

Avoid exposure to direct sunlight as it can discolour and damage the laminate surface.

Furniture laminate is applied to an MDF, chipboard or plywood surface. Here are the main steps for applying laminate:

1. Surface preparation

The surface of the MDF, chipboard or plywood is cleaned and sanded to ensure optimum adhesion.

2. Cutting the laminate

The laminate is cut to size to fit the surface of the furniture.

3. Adhesion of the laminate

The laminate is bonded to the surface of the furniture using a layer of specialised adhesive.

4. Edge finishing

The edge of the laminate is covered with an adhesive tape or profiled with a specialised machine.

Furniture laminate is a versatile, economical and easy to maintain material that offers a wide variety of designs and finishes. It is stain, scratch and water resistant, making it ideal for homes with children and pets. Plus, the manufacturing process is simple and application is quick and easy. If you are looking for an affordable and durable option for your furniture, laminate may be the perfect choice for you.

1. Is the laminate water resistant?

Yes, the laminate is water resistant and can be used in wet areas such as bathrooms and kitchens.

2. Can I clean the laminate with chemicals?

It is not recommended to use harsh chemicals on the laminate surface. Use a soft, damp cloth to clean regularly.

3. Can I cut the laminate myself?

It is recommended that the laminate be cut by a professional to avoid damaging the material and to obtain a precise finish.

4. How can I repair the laminate if it is damaged?

If the laminate is damaged, it can be repaired using a laminate repair kit which includes adhesive and an application tool.

5. How long does laminate last on furniture?

Laminate has a durability of between 10 and 20 years depending on the care and level of use it is subjected to.

6. Can I paint laminate?

Yes, it is possible to paint laminate using a special laminate paint. It is important to sand and clean the surface thoroughly before applying the paint.

7. Is the laminate toxic?

No, laminate is non-toxic and meets safety standards for use in homes and public spaces.

8. Can I use laminate on outdoor furniture?

Laminate is not recommended for use on outdoor furniture as it is not resistant to prolonged exposure to sun and moisture.

9. What designs are available in furniture laminate?

There is a wide variety of designs available in furniture laminate, from plain, monochromatic designs to patterns and textures that mimic wood, marble and other natural materials.

Finish Foil, also known as Decorative Impregnated Paper, is a material used in the furniture and decorating industry to coat surfaces of wood, plastic, glass, metal and other materials to give them an aesthetic appearance and protect them from moisture, wear and tear and scratches. In this article, we will explore in detail how it is manufactured, its applications, advantages and disadvantages, and some important recommendations for its use.

Finish Foil is a decorative material used to coat surfaces and give them an aesthetic appearance. It is a type of paper impregnated with resins and pigments that adheres to the surface through a thermofusion process, creating a protective and durable layer.

Foil was first developed in Germany in the 1970s as a more economical and versatile alternative to other covering materials such as solid wood and laminate. Since then, it has gained popularity worldwide and has become one of the most widely used materials in the furniture and decoration industry.

The manufacturing process involves impregnating a decorative paper with hot melt resins and pigments, creating a product that is resistant to moisture, wear and scratches. The paper is placed in a heat press, where heat and pressure are applied to activate the resins and bond the paper to the surface of the object.

There are different types available on the market, each with its own characteristics and benefits. Some of the most common include:

It is used in a wide variety of applications in the furniture and decorating industry, such as:

It has several advantages that make it a popular choice in the furniture and decorating industry, for example:

Despite the advantages, it also has some disadvantages to be considered:

To keep Finish Foil in good condition, and to use it in furniture and decoration projects, it is important to follow some recommendations:

It differs from other surfacing materials, such as solid wood and laminate, in that it is more economical and versatile. In addition, Foil has a wide variety of designs and colours available and is easy to install.

The installation process varies depending on the surface to be coated and the type used. In general, the manufacturer’s instructions for installation should be followed.

The price of Finish Foil varies depending on the type, design and quality of the material. However, in general, Foil is less expensive than other surfacing materials such as solid wood and laminate.

A wide variety of designs and colours are available, including imitation wood, marble, granite, stone and other natural materials. Abstract and modern designs are also available.

Finish Foil is an economical, versatile and easy to maintain coating material used in a wide variety of applications in the furniture and decorating industry. Despite its disadvantages, it remains a popular choice thanks to the wide variety of designs and colours available, its ease of installation and its resistance to moisture and scratches.

Although it is resistant to moisture and scratches, it may be less heat resistant than other surfacing materials.

Yes, it is a recyclable material.

The price of Finish Foil varies depending on the type, design and quality of the material.

There is a wide variety of designs and colours available, including imitation wood, marble, granite, stone and other natural materials.

Finish Foil is more environmentally friendly than other surfacing materials such as solid wood, as a minimal amount of wood is used in its production.

Gravure printing is a printing technique used in the production of high quality and durable images on a variety of materials, including paper, plastic and metal. In this article, we will delve into the gravure printing technique, exploring its history, process and applications.

Gravure printing, also known as rotogravure, is a printing technique in which an image is engraved onto a surface, usually a copper or steel cylinder, through a series of small raised dots. These dots allow the ink to transfer to the desired surface, creating a precise, high-quality image.

The process dates back to the 19th century, when it was first used to print banknotes in France. Since then, the technique has evolved and has been used in a wide range of applications, including the printing of magazines, catalogues, packaging, wallpaper and labels.

The printing process is complex and requires specialised equipment. The process begins with the preparation of an engraving cylinder, into which the image is engraved using a high-precision engraving tool. Once the image has been engraved, a layer of ink is applied to the cylinder and the excess ink is removed using a scraper. The cylinder is then pressed against the desired surface, transferring the ink and creating the desired image.

Gravure printing has many advantages, including:

Gravure printing is used in a wide variety of applications, including:

When choosing the right printing technique for a project, it is important to consider several factors, such as the type of material, the number of prints and the desired image quality. Gravure printing is ideal for projects that require high image quality and durability, such as labels and packaging. However, for smaller projects with fewer prints, such as business cards, digital printing may be more suitable.

How much does gravure printing cost?

The cost of printing can vary depending on several factors, such as the number of prints, the size of the project and the complexity of the image. In general, gravure printing can be more expensive than other printing techniques, such as digital printing or screen printing. However, for projects that require high image quality and durability, the investment can be worthwhile.

To get the best results in gravure printing, it is important to work with an experienced print provider and to use high-resolution images. In addition, it is important to consider the choice of colours and ensure that they are compatible with the gravure printing technique.

In summary, gravure printing is a high-quality, durable printing technique used in a variety of applications, from labels and packaging to wallpaper and magazines. Although it can be more expensive than other printing techniques, the image quality and durability make it worth the investment in suitable projects.

It can be used on a wide variety of materials, from paper and cardboard to plastic and metal.

Gravure printing uses raised dots to transfer ink, whereas screen printing uses a mesh to transfer the ink.

It is ideal for projects that require high image quality and durability, but may not be the best choice for smaller projects with fewer prints.

The rotogravure printing process involves engraving an image onto a copper or steel cylinder, applying ink and transferring the image to the desired surface.

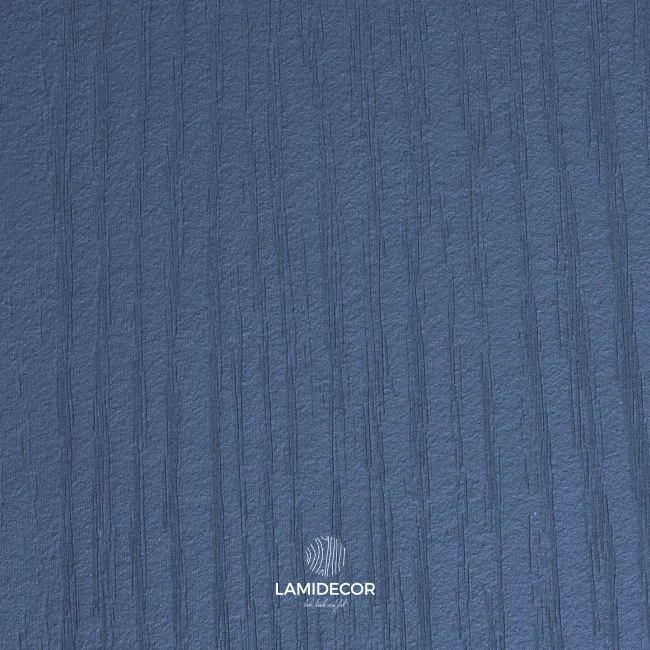

In interior architecture, the appearance of the surface is a key element that contributes to the aesthetics and resistance of the products. Lamidecor presents BRUSHED, the most versatile CPL finish for any design project.

One of the most outstanding features of the Brushed finish of Lamidecor’s CPL Line is its matt and satin appearance.

The Brushed finish has an organic and irregular linear grain that gives it a very natural appearance. Therefore, this wood texture is suitable for a wide range of applications, such as doors, panels, furniture, as well as for edging, thus coordinating all the faces of the pieces.

Lamidecor Brushed Pore is not only perfect for enhancing the natural beauty of wood, but can also be used to create unique and customised designs in a wide range of unicolours. This gives designers and fabricators the freedom to explore a variety of creative options for their projects. Whether it is to give life and expression to a colour, or to bring out the natural beauty and warmth of walnut.

Lamidecor’s CPL finish adapts to all needs. In fact, its relief can be appreciated both to the touch and visually. In addition, when the light shines on it, you can see how it enhances the wood, giving it a very interesting realistic and organic touch.

The motif of this finish exists both vertically and horizontally, creating a linear play of contrast between matt and satin to suit designs in both directions.

All the finishes in Lamidecor’s CPL range are a resistant and durable option for covering all types of surfaces. Its resistance to scratches, bumps and daily wear and tear make it a good choice for high vertical traffic areas.

In addition, Lamidecor’s CPL finish is heat and chemical resistant, helping to protect designs over the long term. It is also easy to clean and maintain – a soft, damp cloth is enough to keep the surface spotless.

Lamidecor’s Brushed finish is the ideal choice for those looking for a versatile and durable finish for their interior design projects. Available in two directions, the brushed finish adapts to any style and design.

Discover the success and versatility of Lamidecor’s BRUSHED finish.

In the dynamic world of interior design and furniture manufacturing, the choice of materials and finishes plays a crucial role in creating functional and aesthetically appealing spaces. In this context, melamine paper has emerged as a true protagonist, offering a unique combination of durability, versatility and aesthetic beauty.

What is melamine paper?

Melamine paper, also known as melamine laminate, is a surface coating material used in the furniture and door industry. It is created by impregnating decorative paper with melamine resins, which produces a tough surface similar to varnished wood. The manufacturing process involves the mixing of resins, impregnation of the paper and drying. Finally, it is pressed together with a substrate, such as paper, particle board or MDF, at different pressure levels, such as LPL, CPL or HPL, to produce a product with various applications in interior design.

Infinite applications

One of the most important characteristics of melamine paper is its versatility in terms of applications. It can be used to cover a wide variety of surfaces, all types of furniture, kitchen worktops, table tops, doors and panels. The infinite number of designs, from wood, colours or fantasies, with haptic and visual finishes, allow the beauty of natural wood to be captured. As well as fooling the user by competing with real materials. Other finishes are surprising and allow designers to give free rein to their creativity.

Resistance and Maintenance

The resulting melamine paper is excellent in terms of durability and ease of maintenance. Its non-porous surface makes it resistant to water, heat, scratches and stains, making it a perfect choice for high traffic areas such as kitchens and bathrooms.

Conclusion

Melamine paper is essential in the manufacture of furniture, doors, etc. Its precise manufacturing process, versatility of applications and durability make it an obvious choice for those looking for a high performance and aesthetically pleasing material. If you are looking for a solution that combines beauty and functionality in your projects, look no further than melamine paper. This material has proven to be the versatile star that raises the standard in surfacing and creating quality furniture.

In the competitive world of interior design and decoration, finding a coating that combines versatility, quality and durability is essential. In this regard, Lamidecor, a leading company in the decorative paper industry, has a solution that has revolutionised the way we see and use laminates. This is LUKS quality, a unique laminate that stands out for its multifunctionality, flexibility and excellent opacity.

LUKS: Versatility in Surfaces

LUKS, developed by Lamidecor, is a response to the growing demand for a laminate that can be adapted to a wide variety of applications. Its versatility makes it ideal for flat surfaces (panels, chipboard, MDF, hardboard and plywood) and curved surfaces (profiles). Its ability to adapt to different types of materials makes it an attractive option for a wide range of interior design and architectural projects.

Quality Composition

LUKS laminate is composed of cellulosic papers that can be printed with water-based inks on a cellulosic fibre backing; together with the melamine and aminoplastic resins used in its manufacture, it provides a product with good solid strength and exceptional durability.

Opacity

LUKS laminate stands out for its excellent opacity ensuring uniform coverage and a flawless appearance on all surfaces.

Performance and Durability

LUKS has excellent physical properties, as it is able to withstand daily use without losing its attractiveness. This is due to its good strength and flexibility, which make it a tough and adaptable choice. In addition, its lightfastness ensures that colours remain vibrant over time.

Optional Antibacterial Property

For projects that require an additional level of hygiene and protection, Lamidecor offers LUKS quality with anti-bacterial properties. This option provides an additional layer of safety in applications where hygiene is a primary concern.

LUKS in Interior Design

But LUKS is not just limited to surface coatings. It also excels in the world of interior design as a high quality decorative paper. Forming part of Lamidecor’s wide range of decorative paper qualities, LUKS is the ideal choice for those looking for a coating to suit all their creative needs.

Versatility in Design

For those looking to add a tactile dimension to their designs, LUKS offers the option of applying a CPL (Continuous Pressure Laminate) finish. This process adds texture to the surface, allowing users to experiment with different sensations when touching and exploring the design.

Countless Creative Possibilities

In short, LUKS by Lamidecor is a multifunctional laminate that redefines the way surfacing is conceived. Its versatility, quality and durability make it an outstanding choice for a wide range of interior design and architectural applications. With LUKS, the future of interior decoration and creativity in space design looks brighter than ever.

In the exciting world of interior design, every detail counts in creating a space that reflects the personality and style of the homeowner. Among the elements that often go unnoticed but play a crucial role in the aesthetics of a room are moldings, profiles, and baseboards. Traditionally, decorative paper has been the preferred choice for covering these surfaces, but today, an innovative option has arrived to revolutionize the market: inkjet-printed vinyl film.

Advantages of Inkjet-Printed Film

This inkjet-printed film offers a number of advantages that make it a standout choice for molding and baseboard decor:

For those looking for the best quality in paper and surface covering, it’s no surprise that this decorative vinyl film comes from Lamidecor. A leading company in the industry. With an established reputation for manufacturing decorative paper and other covering materials, Lamidecor has brought its expertise and quality to the world of inkjet-printed films. Its products meet the highest standards of quality and design, giving interior designers and homeowners the confidence that they are using the best in surface covering.

In conclusion, inkjet-printed vinyl film represents the future of molding and baseboard decor. Its versatility, digital printing, moisture resistance, and the possibility of custom finishes make it a leading choice in the market.

In the world of interior design and furniture, surface finishes play a fundamental role in the appearance and durability of products. Lamidecor, a leading company in the decorative paper market, presents an interesting new CPL finish. The Corteza pore will make any design stand out.

The term “CPL” stands for “Continuous Pressure Laminate”. It is a type of finish used on furniture surfaces, doors and other decorative elements. The CPL finish is obtained by combining thermosetting resins, decorative papers and melamine layers. This process is carried out under high pressure and temperature, creating a highly resistant and durable final product.

One of the most outstanding features of the Corteza finish of Lamidecor’s CPL Line is its matt appearance and its very marked wood structure. This provides a natural and authentic look, similar to real wood. The matt finish is also ideal for reducing reflections and fingerprints on surfaces, maintaining a clean and elegant aesthetic.

In addition, this Lamidecor pore is not only available for use with different types of wood, but also in a wide range of unicolours. This gives designers and manufacturers the freedom to explore various creative options for their projects. Whether it is a minimalist design or a bolder and more colourful one, Lamidecor’s CPL finish suits all needs.

The CPL is known for its high strength and durability. The laminated surface is resistant to scratches, bumps and daily wear and tear, making it an ideal choice for applications that require a robust and durable surface. In addition, Lamidecor’s CPL finish has excellent heat and chemical resistance, ensuring that designs retain their beauty over time.

Another significant advantage of Lamidecor’s CPL finish is its easy maintenance. Unlike some finishes that require special care, this type of finish is simple to clean and maintain in optimum condition. A soft, damp cloth is enough to keep the surface spotless.

Lamidecor‘s innovative CPL Cortex finish enhances any design with its visual and tactile appearance, giving designers creative freedom. From furniture to doors and panels, this finish adds character to the final products.

Lamidecor is a leader in the world of decorative paper, with a solid reputation for continuous innovation, quality and excellent customer service. The new Corteza finish offers a world of possibilities for designers and manufacturers in the field of furniture and interior design. Its matt finish and marked wood structure make it an interesting and natural choice, ideal for commercial and residential projects. With Lamidecor leading the decorative paper industry, designers can have full confidence in the quality and impact of their creations.

At Lamidecor, we are proud to present our Design Department, the creative heart of the company. Here at Lamidecor, we have a highly talented multidisciplinary team dedicated to creating realistic motifs for decorative paper design. Our aim is to bring you high quality designs that add beauty to any space.

The first step in the process of creating our designs is a state-of-the-art scanning of materials such as natural wood veneers. Veneers, marble and stone are carefully selected for their quality and beauty. We use state-of-the-art technology to capture very high resolution images that reflect every last pore of texture and depth of detail unique to each piece.

Once we have the scanned images, our design team processes them and creates beautiful, authentic designs. We use specialised software to manipulate the images, adjusting colours, contrasts and other elements to achieve stunning results.

Our design team draws inspiration from a wide range of styles, from the natural beauty of wood to other materials, fantasies and geometric patterns. Each design is created with dedication and attention to detail, to meet the needs and preferences of our customers.

Before launching our products on the market, we carry out extensive fit testing and retouching. It is important to ensure that the designs fit perfectly on different surfaces and maintain their natural appearance and texture.

Once the designs have passed the fit and touch-up tests, we proceed to the lacquering and finishing process. This stage is crucial to achieving the natural look and feel of our products. Numerous factors are taken into account, from the degree of gloss, to the haptic and visual texture. Our design team can create pores synchronised with the grain of the wood, as well as 3D embossed finishes, and even achieve an anti-bacterial surface.

We lacquer and finish to ensure that our products look authentic and durable. In this way, we ensure that the designs are protected and maintain their beauty over time.

At Lamidecor, we pride ourselves on offering the highest quality products that achieve a lifelike appearance and natural texture. Thanks to our careful creation process, our designs are realistic, detailed and create a warm and welcoming atmosphere in any space where they are used.

Aplicamos nuestros productos en diferentes superficies, como puertas, molduras, mobiliario y paneles, para brindarles un toque especial y transformarlos con estilo. Nuestro Departamento de Diseño de papel decorativo se esfuerza por crear diseños únicos y atractivos que satisfagan las necesidades y gustos de nuestros clientes. Ya sea que estés buscando revestir una puerta, decorar una moldura o darle un toque especial a tu mobiliario, nuestros productos son la solución perfecta.

We apply our products to different surfaces, such as doors, mouldings, furniture and panels, to give them a special touch and transform them with style. Our Wallpaper Design Department strives to create unique and attractive designs that meet the needs and tastes of our customers. Whether you are looking to cover a door, decorate a moulding or add a special touch to your furniture, our products are the perfect solution.

At Lamidecor we have a highly talented Design Department that is dedicated to creating realistic decorative paper motifs, from the scanning of the materials to the lacquering and finishing process. Each stage of our creation process is designed to deliver high quality products and add beauty and elegance to any space.

We are committed to providing aesthetic and functional solutions to our customers who wish to transform their environment with unique and quality designs. Feel free to contact us and discover the endless design possibilities we offer. We will be happy to work with you to transform your ideas into reality.